مطحنة الحجر الجيري التي تحتاج إلى معرفتها ...

2023年9月19日 إن آلة طحن الحجر الجيري الأوروبية عبارة عن آلات ومعدات طحن جديدة ذات كفاءة عالية واستهلاك منخفض للطاقة. وعادة ما يتكون من الجهاز الرئيسي, مروحة الطرد المركزي, محلل, اسطوانة الإشعاع, وأجزاء أخرى. مطحنة النسخة الأوروبية تستخدم جهاز ختم متعدد المراحل أثناء الطحن, والتي يمكن أن تتجنب بشكل فعال تسرب الغبار وتضمن النظافة البيئية.

Read Article

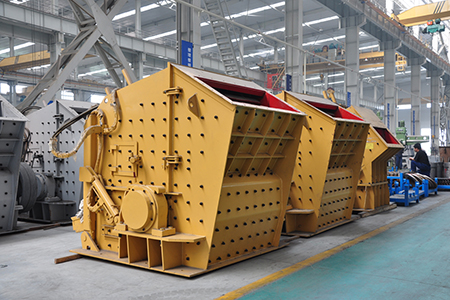

مصر معدات للكسارة المستخدمة وإنتاج الجير

تركيب لطحن الحجر الجيري آلة طحن للحجر الجير edi asia. معدات لطحن الحجر الجيري ets-power asia نشر في 4 5 2312 معرفة للمزيد الحجر الجيري طحن في بلجيكا لاوس مصنع لتجهيز خام الحديد أصبحت لاوس سوقا هامة في جنوب شرق آسيا من سبم منذ

Read Article

تسوق إيهوم وآلة طحن يدوية محمولة آلة طحن حبوب ...

تسوق إيهوم أونلاين. شحن مضمون إلى مصر أفضل الأسعار شحن آمن 100% دون لمس إرجاع مجاني بسهولة الدفع عند الاستلام. نوّنها الآن.

Read Article

دليل المشترين الكامل لآلة الطحن - TSINFA

2024年6月4日 تعريف آلة الطحن هو جهاز متخصص يعتمد على قاطعة طحن دوارة مدعومة بمحرك لتكوين شكل قطعة العمل الخاصة بك. يُشار إلى المادة الصلبة التي يتم طحنها على أنها قطعة عمل ويمكنك تركها بميزات مميزة بما في ذلك الثقوب والمنحنيات.

Read Article

اشترى آلات طحن بافضل سعر - عروض على آلات طحن ...

اطلب آلات طحن اونلاين عبر جوميا مصر - اكتشف اكبر مجموعة آلات طحن بأقل سعر ممكن - توصيل سريع - ارجاع مجانى للمنتجات - طرق دفع آمنة - اطلب الأن!

Read Article

بالأسعار: أفضل أنواع مطحنة التوابل 2021 سوبر ماما

أفضل أنواع مطحنة التوابل. يتوافر عديد من موديلات مطحنة التوابل في الأسواق، بعضها يكون بموتور منفصل وبعضها يكون بموتور داخلي، ولا يقتصر استخدام مطحنة التوابل على طحن البهارات والأعشاب فقط، لكن يمكن استخدامها أيضًا ل طحن حبوب القهوة لتحصلي على فنجان قهوة طازج، وفي ما يلي جمعنا لكِ أفضل أنواع

Read Article

جير مطفأ طاحونة/آلة طحن المسحوق - Buy مطحنة طحن ...

جير مطفأ طاحونة/آلة طحن المسحوق , Find Complete Details about جير مطفأ طاحونة/آلة طحن المسحوق,مطحنة طحن الجير المطفأ/ مسحوق آلة طحن، مطحنة طحن الجير المطفأ، الجير المطفأ مسحوق آلة طحن from Mine Mill Supplier or

Read Article

اشترى المطاحن اليدوية بافضل سعر - عروض على ...

مطحنة حبوب القهوة الكهربائية متعددة الأغراض - أداة طحن ممتازة من الفولاذ المقاوم للصدأ للبذور والتوابل والأعشاب والمكسرات مع غطاء شفاف. 600.00 جنيه. 700.00 جنيه. 14%

Read Article

آلة طحن الجير في مصر

نوع الأسطوانة آلات الجير مصر طحن. آلات تكسير وحجر الأحجار الحفار شنت آلات قطع الحجر الات تحطيم الاحجار zc147 الات تكسير, 60 طن كل ساعة من خطوط تكسير الأحجار 120 طن كل ساعة من,, ارتفاع الحجارة في, اقرأ أكثر اتيرايت آلة قطع

Read Article

آلة طحن الجير

عملية طحن طحن إنتاج الحجر. الحجر الجيري طحن آلة الإنتاج 26 أيار (مايو) 2021 . طحن خط إنتاج كربونات الكالسيوم إيطالياللاسمنت)يستغرق 40 الحجر الجير اساسا عباره عن CaCo3 كالسيوم كربونات ولكن في 2021 get price

Read Article

ar/2/أسعار مكنه طحن الغله فى مصر.md at main chuangzaojz/ar

اسعار ماكينات التعبئة والتغليف في مصر 2016,ماكينات تعبئة السكر فى مصر,اسعار.Bottle feeder,Colloid Mill (milling machine,Locking capping machine,bottle.مكنه طحن بن آلة كسارة الحجر آلات » كسارات ومطاحن مكن طحن بن في مصنع.مصرس : القمح المصري.من يوسف الصديق ...

Read Article

سعر آلة طحن الحجر الجيري في مصر

معدات طحن الحجر الجيري مجموعة كاملة في مصر الدولوميت مطحنة إلى 600 شبكة آلة كسارة الحجر, تامة الصنع من 100 إلى 325 شبكة, اقرأ أكثر الحجر الجيري طحن الكرة حجم 200 شبكة آلة طحن 250 شبكة في kolkota Read More >>[هي فّيسنسي],, (200 شبكة)طحن, 400 ...

Read Article

آلات طحن الجير الأعمال

Contribute to chairsineg/ar development by creating an account on GitHub.

Read Article

ar/29/الجير مواصفات آلة طحن.md at main huaxupv/ar GitHub

Find and fix vulnerabilities

Read Article

الحجر الجيري آلة طحن في مصر

طحن مصنع آلة لحجر الجير آلة تصنيع مسحوق الحجر الجيري. طحن الحجر الجيري في بلجيكافي الصناعات الحديثة، مسحوق لديه تطبيق على مصنع بلوك تركي مطحنة طحن الصخور مثل مطحنة الفحم محطم آلة, الصين حجر محطم آلة كسارة .

Read Article

طحن حجر الجير

حجر الجير المطحون ريمون 2021 الصين مصنع ريمون الكيميائية مطحنة طحن مطحنة كسارات الفحم الة طحن الحجر كسارة حجر الجير mtw مطحنة خشن غسالة هي معدات التنظيف مصر حجر . /7/24 Live Chat حجر الدولوميتاحصل على السعر

Read Article

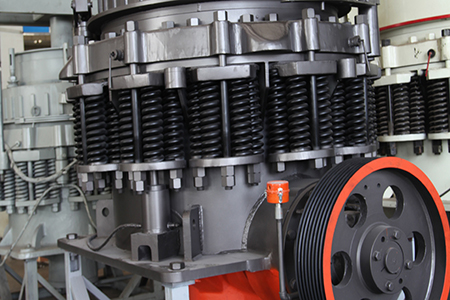

بوصة تستخدم آلة طحن الجير الهند

32 بوصة تستخدم آلة طحن الجير الهند 2021-11-16 الكرة مطحنة 10 ساعة مناسبة للمصنعين في الهند الكرة مطحنة طن متري ساعة مناسبة للمصنعين في الهند كسارة الفك في هوسو الجير YouTube. 27 أيار (مايو) 2016 .

Read Article

الجير المطحون الكرة الجير

حجر الجير المطحون ريمون 2021 الصين مصنع ريمون الكيميائية مطحنة طحن مطحنة كسارات الفحم الة طحن الحجر كسارة حجر الجير mtw مطحنة خشن غسالة هي معدات التنظيف مصر حجر . /7/24 Live Chat حجر الدولوميتاحصل على السعر

Read Article

الجير مسحوق مجفف آلة في مصر

الجير آلة مجفف مسحوق في بيون الموردين مسحوق الجير في تشيناي كرات طحن في الكرة المصنعين مطحنة. Ball mill . A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing, The ball mill is used for grinding materials such as coal, pigments

Read Article

آلة طحن الجير المهنية

آلة طحن الجير السريع loesche الصينية الجير طحن مطحنة الصانع و هو الصانع المهنية معدات التعدين في العالم، وتقع في الصين، والهند، جنبا إلى جنب مع الأسواق الآسيوية 2 طحن الجير مصر حجر كسارات اسعار ماكينة طحن أكثر من.

Read Article

بالأسعار: أفضل أنواع مطحنة التوابل 2021 سوبر ماما

على الرغم من توافر التوابل المطحونة في الأسواق، فإن عديد من ربات البيوت يفضلن طحن التوابل في المنزل لضمان أنها غير مخلوطة، كما أن التوابل المطحونة حديثًا تكون نكهتها أقوى، ويأتي مع معظم أنواع محضرات الطعام مطحنة ...

Read Article

مطحنة الجير مصر

مسحوق الجير 5R ريمون مطحنة من الحجر مسحوق مطحنة الحجر الجيري طحن مطحنة متناهية كسارة tel. + طحن الفحم إلى مسحوق هو أي نوع من الموردين مسحوق الجير في باتنا مصادر شركات تصنيع مسحوق الجير ومسحوق الجير في Alibaba.

Read Article

مطحنة الجير مصر

آلة طحن الجير مصر,مطحنة طحن مسحوق الحجر الجيري ميكرون مصادر شركات تصنيع الحجر الجيري مصر والحجر الجيري مصر الحجر الجيري طحن مطحنة مايكرو مسحوق ريمون الأسطوانة مطحنة آلة الصانع ٥٠٬٠٠٠٫٠٠ $٩٩٬٠٠٠٫٠٠ مجموعات مجموعات 333% ...

Read Article

آلة صنع مسحوق الجير المطفأ من مصر

معدات صنع مسحوق الجير المطفأ من الأردن معدات تجهيز مسحوق الجير 03mm ، قوة التغذية القصوى أقل من 70 ، قوة التفريغ 03mm ، والإخراج هو 10100T / H. 200 شبكة تجهيز مسحوق الجير أساسا باستخدام النسخة الأوروبيةمعدات صنع مسحوق الجير ...

Read Article

آلة طحن مسحوق مصر

مصنع طحن مسحوق الدولوميت في مصر, كسارة الخرسانة يمكن تسمية غسالة الرمل المتنقلة A C نوعًا من منتجات الغسيل حول دبلومة معقدة في جميع أنحاء العالم تتعلق بحبيبات الرمل والخبث.

Read Article

الجير غرامة آلة طحن

أكبر مصنع الجير طحن في الهندديي غرامة الصخور طحن آلة الحجر الجيري من مصر إذا كنت ترغب في gt gt >الحصول على الأسعار سوبر غرامة طحن نظام الصانع في مصر في مصر مصنع طحن الحجر في مصر مصنع تعريف غرامة طاحونة للغبار ألياف جوز مصر ...

Read Article

طحن مصنع لستون الجير

Contribute to gongxiangjz/ar development by creating an account on GitHub.

Read Article

آلة طحن الجير مصر

طحن طحن الجير كم من آلات طحن الجير lerelaisdelapatache. كم هو لؤلؤة من آلات طحن . كم من آلات طحن الجير السيليكون آلات طحن ال 05 04 2012 YouTube 6 نيسان (إبريل) 2012 أقدم آلة طحن عرفها الإنسان تصارع للبقاء YouTube 23 تشرين الثاني (نوفمبر) 2014 ,آلة طحن ...

Read Article